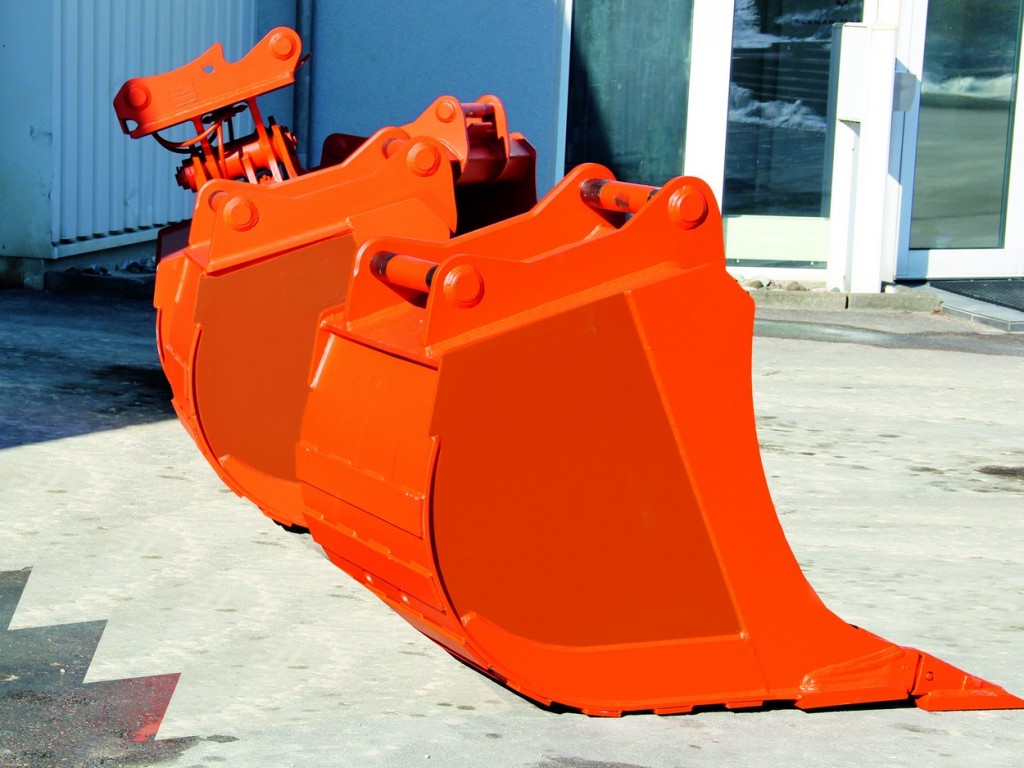

1.0 Series Bucket – Made by ZFE

Lighter – More Stable – More Efficient – SIMPLY BETTER

Since the end of 2013, the heavy equipment accessory manufacturer ZFE has been a member of the HS-Schoch group. A year after consolidation, the company is offering a new range of products. „We don’t want to do necessarily everything differently, but there’s a lot that we can do better“ says Hermann Schoch. „Therefore, we’ve spent the last year developing a new line of products. The experience of ZFE combined with the expertise and resources of the HS-Schoch companies opens up a new realm of possibilities. And we’ve taken advantage of this opportunity”

It started with the mini-bucket series which was first presented to the public at the GalaBau in Nuremberg. Currently, the southern German bucket manufacturer is focusing on compact buckets for smaller excavators.

„The name of the Series 1.0 line was very deliberately chosen. We want to start with a clean slate, and this expresses that perfectly“ explains Hermann Schoch. „This year we will also release new buckets and blade types under the Series 1.0 label. We are currently in the testing phase“

Series 1.0 Backhoes During the first year of ZFE’s membership in the HS-Schoch group, ZFE engineers developed a wide variety of technical innovations, all of which have been implemented in the Series 1.0 line.

In particular, the new ZFE buckets has better penetration than ever before while maintaining very good scooping and dumping characteristics. Months of development work has increased the handling capacity per liter of diesel by more than 10%.

The low-cut sides of the buckets lower resistance and reduce the excavator’s energy consumption. A bended upper cover plate and additional inner edge lining ensures a stiffer construction and better performance, even at low heights. Due to these design characteristics, the bucket has a higher tensile strength than conventional designs. To ensure optimal penetration, the Series 1.0 line of buckets are available with cutting or tooth systems from MTG, ESCO, CAT or to an individual customer’s specifications.

Series 1.0 Backhoe our careful selection of materials, such as the use of high-strength steel for all stress and impact prone locations as well as the lowest manufacturing tolerances make our new bucket extremely robust and guarantee a strong service life. Additionally, we utilize Borox surgical stainless steel due to its excellent resistance to wear and tear as well as its resistance to breakage. This is due to the special heat treatment process it goes through, which makes it extremely tough.

Series 1.0 Backhoe our careful selection of materials, such as the use of high-strength steel for all stress and impact prone locations as well as the lowest manufacturing tolerances make our new bucket extremely robust and guarantee a strong service life. Additionally, we utilize Borox surgical stainless steel due to its excellent resistance to wear and tear as well as its resistance to breakage. This is due to the special heat treatment process it goes through, which makes it extremely tough.

Hermann Schoch has placed an emphasis on making all ZFE products in Germany. All steps of manufacturing take place in Germany, from metal cutting to final painting.

Our new Series 1.0 compact bucket will be displayed at INTERMAT in Paris. On April 20-25th, ZFE will be located in hall 6, Stand G 03.