ESCO

ESCO: Tooth systems, shields and wear plates

For more than 90 years ESCO produces wear-resistant products such as tooth systems, shields and wear plates for backhoe buckets, rock buckets, swivelling backhoe-buckets, loading shovels, Lattice buckets / rock buckets, grating buckets, trapezoidal buckets and tunnel buckets etc. ESCO products are used in the mining industry, in construction, in crushing plants, in dredging, in conveyors, in demolition, in recycling and in forestry.

ESCO is a leading manufacturer of technically sophisticated earthmoving equipments and durable wear parts, which are used in construction and mining, dredging, and recycling. ESCO manufactures, on the basis of a high technical know-how and expertise, in metallurgy high-quality products and tooth systems for buckets, grabs, clamshell grabs / 2 double-shell type grabs, loading shovels, ripper tooth and ripper buckets.

ESCO is a leading manufacturer of technically sophisticated earthmoving equipments and durable wear parts, which are used in construction and mining, dredging, and recycling. ESCO manufactures, on the basis of a high technical know-how and expertise, in metallurgy high-quality products and tooth systems for buckets, grabs, clamshell grabs / 2 double-shell type grabs, loading shovels, ripper tooth and ripper buckets.

Furthermore ESCO manufactures numerous critical components for the aerospace and power generation.

Benefit from our ESCO products

ESCO – tooth systems such as ULTRALOKTM, SUPER V®, SV2® increase the performance of buckets, grabs, clamshell grabs / 2 double-shell type grabs, universal grabs, demolition grabs and sorting grabs, ripper tooth and ripper buckets while reducing costs and downtimes.

ESCO Ultralok tooth system

ESCO Ultralok is an innovative and cost-effective tooth system for backhoe buckets, rock buckets, swivelling backhoe-buckets, trench clearing buckets / swivelling, Lattice buckets / rock buckets, trapezoidal buckets and tunnel buckets etc. Unlike conventional tooth systems, which consist of three parts, the Ultralok system consists of only two parts, thanks to a completely new revolutionary integrated fuse.

ESCO Ultralok is a real hammer-free system, not just a hammerless fuse. ESCO Ultralok makes a safe and easy change of tooth locally possible and reduces the storage.

The ESCO Ultralok® tooth system has more to offer for backhoe buckets, rock buckets, swivelling backhoe-buckets, trench clearing buckets / swivelling, Lattice buckets / rock buckets, trapezoidal buckets and tunnel buckets etc.

More reliability:

The ESCO Ultralok tooth system has 10 percent more stable fitting surfaces than products from competitors. In addition, the tooth backup is burdened considerably less due to its special position, which considerably reduces the wear.

Easy application:

A wedge integrated in ESCO tooth, a unified fuse size for all ESCO Ultralok tooth systems and the easy access to fuse for changing teeth on excavators an easy task.

More safety:

ESCO Ultralok is a completely hammerless tooth system. With a simple crowbar tool, the entire ESCO Ultralok Tooth System of the bucket tooth can be attached and detached on the holder. It does not require any hammer. This decreases the risk of injury.

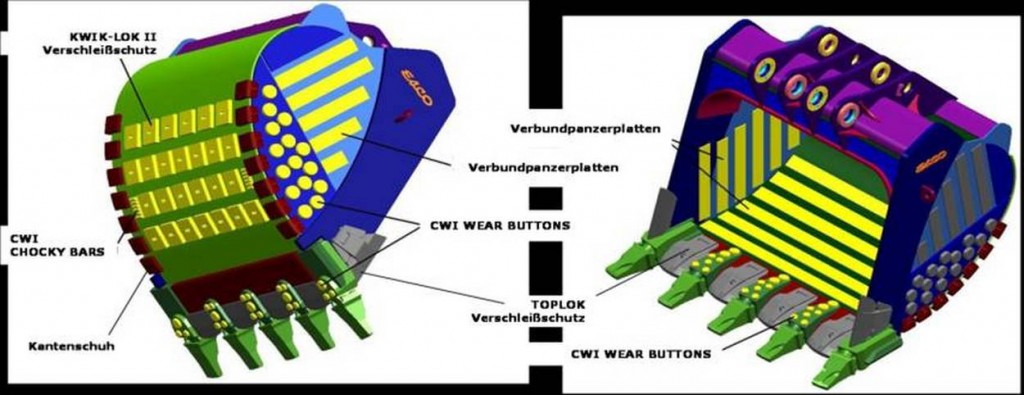

ESCO Toplok® Shields

ESCO TOPLOK® are mechanically attached shields that ensure excellent protection of the lip during good penetration:

ESCO KWIK-LOK ® offers an efficient protection against wear on buckets, backhoe buckets,

rock buckets, swivelling backhoe-buckets, trench clearing buckets / swivelling, Lattice buckets / rock buckets, trapezoidal buckets and tunnel buckets etc.: Also dragline shovels, folding shovels, high buckets and loading shovels and grating buckets can be protected from wear optimally by ESCO KWIK-LOK wear plates.

rock buckets, swivelling backhoe-buckets, trench clearing buckets / swivelling, Lattice buckets / rock buckets, trapezoidal buckets and tunnel buckets etc.: Also dragline shovels, folding shovels, high buckets and loading shovels and grating buckets can be protected from wear optimally by ESCO KWIK-LOK wear plates.

ESCO Toplok® shields can be easily and quickly replaced on site. In addition to the fully mechanized shield, a weld-on base plate and a wedge also belongs to the ESCO Toplok system.

The Toplok® shields casted, made of thorough-hardened ESCO alloys are ideal for abrasive use and provide good protection against impact loads.

Advantages of the Toplok® Shields

Longer service life:

ESCO Toplok® shields effectively protect the cutting edge of the lip, thus extending the operating time. The special construction method ensures an optimum penetration and simultaneously optimum protection of the lip. And the absence of holes reduces the risk of fractures at the lip.

- Fast and easy replacement

- Available as standard and Rock Version

ESCO Kwik-Lok® II Wear-Protection

Mechanical fuse system makes changing quick, easy and safe. ESCO is the inventor of the mechanical, quick-change wear protection system.

Versatility:

Three system sizes and four different versions of base plates provide protection for a wide variety of usages. A particularly wear-intensive position can be protected by a single wear plate or an entire surface can be protected by several wear plates.

Safe and Easy:

Simple, one-piece wedge ensures easy and fast assembly and disassembly without special tools. To replace the wear plates, no welding or adaptation of large wear strips are required. Light wear plates reduce the risk of injury, and no crane is required to be used.

Long lifetime:

To ensure a long service life and to ensure up to fivefold service life of the conventional steel strips, the wear plates in the ESCO alloy 12S – 514HBN – are casted. Wear plates in the alloy 35S are available in special sizes to achieve an increased service life with low load during usage. The Kwik-Lok® II wear plates are rotatable to achieve improved service life during usage with uneven wear.

Less maintenance – improved service life:

The ESCO wear plates are assembled and ready for installation. It does not require any handling or preparations. No welding off or cutting of steel bars is necessary to change the Kwik-Lok® II wear plates.

After the installation of the base plate, the wear plate can be replaced within a few minutes, and no visit to the workshop is required. ESCO wear plates can be rotated, reversed and changed within a few minutes.